Spring semester 2017 at Rice. Now it was time to get serious. I had a real project to complete and people were counting on me. At this point, I still had essentially no experience with electronics.

Quick disclaimer:

This is just a small project that was taking part in REV during this time period. It was the one I was involved with and knew the most about. The rest of the team (both ELEC and MECH) were busy working on their own projects. They were working on a brakes system, a compound gear drivetrain design to implement a large gear ratio, a motor controller, and probably many more cool things during this time period.

Where’s the team?

The initial interest of members in PowerSense was pretty huge, but naturally many of them began to disappear over the weeks. Additionally, as a freshman, I started to say yes to everything and wasn’t able to find convenient times to work with others. However, a good core team remained determined to finish the project, consisting of about 3-4 freshman.

Meanwhile, the upperclassmen were handling the big fish, the motor controller. At the moment I didn’t know much about it and didn’t realize the importance of it in the class. Damien (MECH, 2018), Clark (MECH 2018), and Irene (ECE 2019) were the true ELEC heroes of that semester. While I and some freshman played around with circuits, they were really the ones doing the tough work and putting that motor controller together. They spoke of SPI communication, 4-layer PCB design, etc, and at the time I didn’t understand anything they were saying.

Setting a deadline…

I thought I needed some type of deadline to finish the PowerSense controller, so I heard about and chose to sign up for ECE corporate affiliates day, on Mar 31, the day before beer bike. Of course, I didn’t know what I was doing. I didn’t know this event was heavily sponsored, and the people presenting were mostly large research teams under the leadership of a professor, or maybe some senior design teams with some remarkable projects. Either way, I signed up, and now I had this looming deadline of when to deliver this project.

PowerSense:

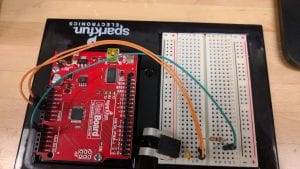

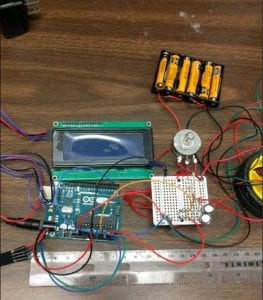

I started to do some research on what type of sensors to purchase, and how to setup the system. I decided on the ACS758 hall effect current sensor to be placed in series with the entire load of the car. I also decided on using 2 resistors in parallel with the entire load, to set up a voltage divider from the battery to a sub-5V voltage the Arduino could read. So the Arduino would read a current reading and a voltage reading from its ADC inputs, and then multiply the two together and output a reading through a 20×4 character display.

Additionally, a hall effect sensor would be used to determine the speed of the wheels. Through a reading of the speed of the car, we could divide efficiency/speed to get an accurate reading of efficiency across different speeds.

So we got to work and around mid-February we had some early prototypes on a breadboard of what we were doing.

But everything wasn’t perfect. The demos were really finicky, and this ACS758 current sensor never seemed to work well for us. It might’ve been because we were testing at such low current ratings. Either way, nothing tangible worked, and by March it was getting really close to the Affiliates day.

The last week:

I felt like I needed a good demo I could show at affiliates day. The optimal demo would have been the real sized large motors spinning a wheel. The user would’ve been able to press on the accelerator pedal to change the speed fo the wheel, and they would’ve been able to see the “efficiency” of the car changing as the speed change. However, due to time constraints and expertise, I knew a demo of this scale would be unlikely to come together in time for affiliates day.

At the end, I decided the 2 main goals of the demo would be:

- For people to get an idea of what the goal of how a power sensor could benefit us

- Have the demo be interactive where the user could play with it.

With these things in mind, I decided to build a simple demo of PowerSense. It was down to the last week before the affiliates day. Although it was the busiest week of the semester, I was fortunate enough to have some members from REV still be willing to help me out.

I went inside of the Ethernest lounge in Abercrombie (it’s now the master students lounge), and spent a week with a couple other REVers building this demo. the room didn’t have any windows, and the entire Ethernest was essentially completely abandoned at this time. Aside from this I had other projects to do for classes, midterms, homework, and beer-bike training/activities during this week, and so did the rest of my teammates. As far as I can remember, it was one of the busiest weeks I’ve had in college.

Demo

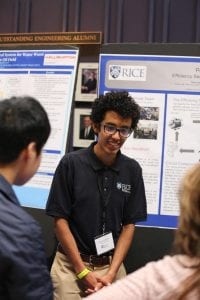

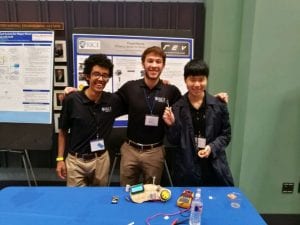

By Friday morning, we had a little working demo, and a poster. I felt so relieved having survived that week. We walked across the street to Duncan hall and gave our presentation/pitch.

At the end of the day, we were pretty proud of our demo. I think we were the only fully-freshman team to be at this showcase, even though our demo was simple. We also got pretty cool collared ECE shirts to keep.

We also presented this Demo at the Engineering Design showcase under the REV booth, and on the last day of ELEC 220 during presentations.

Aftermath

I did some thinking after the showcase, about what the project meant. A group of us put a lot of time and energy behind this project. I learned a lot of practical engineering knowledge throughout the project and good ways of working with others.

Despite all this, after the showcase had ended we only had a demo and not something tangible that we could put in the car that could directly benefit us in competition. I did some thinking and knew that working on the Motor controller would be the best way to ensure future success for the team.

I still wanted to be involved with the REV team, and help build other awesome things like the motor controller, and even learn more about the mechanical aspects of the car. I decided to apply for the Chief Engineer position in REV next year. The following year to come would be filled with a lot of learning and a lot of work.

Part 3 (2017-2018 and competition) coming soon…